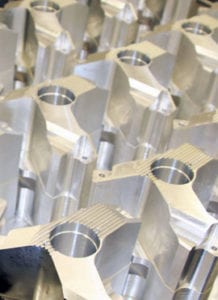

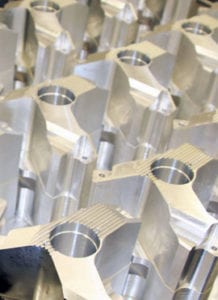

CNC Milling/Machining

Complex Cable Harness Build

Cable Testing

Integration Testing

Environmental Stress Screeing

Laser Assembly & Testing

Mechanical Assembly

Custom Case & Foam Fabrication

Vertically Indexed and Matrixed

CNC Milling/Machining

Complex Cable Harness Build

Cable Testing

Integration Testing

Environmental Stress Screeing

Laser Assembly & Testing

Mechanical Assembly

Custom Case & Foam Fabrication